Top 18 sàn gỗ sân vườn ngoài trời + Thi công sàn gỗ nhựa ngoài trời

Decorating outdoor garden spaces to perfect the interior and exterior for a comfortable living space is always what many people aim to improve the quality of life.

What is garden wood flooring?

Garden wood floors are specialized flooring products for garden spaces or outdoor decorations with high heat resistance, stable when the weather changes. Currently, besides natural flooring products for garden, outdoor plastic wood flooring products, cement wood flooring are the most optimal choices because of the long material life and no additional maintenance costs. periodically. So what kind of wood flooring for the garden area to choose so that the quality of the floor ensures over time use and saves on finishing costs?

What types of garden wood floors are there?

Garden laminate flooring is currently popular with 3 basic materials: natural wood, outdoor plastic wood and cement wood with unique characteristics of each line to suit all exterior decoration requirements.

Natural wood

Any type of natural wood plank can bring great beauty to the floor space, but the finishing and maintenance cost is always something that everyone should consider when choosing this material. Depending on the type of natural wood floor and the thickness, the durability of the floor is not the same, natural wood flooring is easy to warp because of heat and easily damaged by mold, termites.

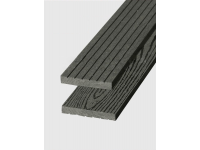

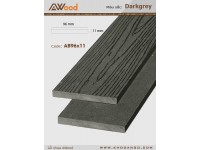

Outdoor plastic wood

Outdoor plastic wood is mainly composed of virgin resin, natural wood pulp and additives with different percentages depending on the characteristics of each brand. Outdoor plastic wood overcomes most of the shortcomings of natural wood planks in terms of color fastness, stability when temperature changes, water resistance, termite resistance, ... are a perfect substitute for traditional flooring.

Cement wood

A product line with the main ingredient of 75% cement stone powder, 23% cotton fiber mesh and 3% colorant binder for the complete product with a luxurious wood grain surface and a sturdy cement floor that is rain-resistant sunny. Besides the outdoor plastic wood line, cement wood is also a popular flooring product that many people choose.

What kind of wooden floor should be used for the garden

With garden space or exterior decoration in general, the selection of stable flooring for long-term use under erratic weather changes ensures that the finishing price is not too expensive to pay more attention. in finishing the interior space is essential. Therefore, choosing expensive natural wood flooring material that costs extra periodic maintenance costs is not necessary, outdoor plastic wood flooring and cement wood flooring with the brands: AWood, Ultra Awood, ATWood, EXWood, CONWOOD, ... are current high-quality outdoor flooring brands.

Explore more:

What is WPC synthetic resin wood? Application of WPC plastic wood

Quotation of outdoor wooden flower truss + Construction of Awood plastic wooden frame

Things to know about outdoor plastic wood materials

Outdoor wooden decking for swimming pool

Construction of outdoor plastic wooden floor

Outdoor plastic wood with 2 main types are wood flooring and outdoor wooden blisters. With outdoor wooden blisters, users can work by themselves by assembling the wooden blister together into joints and with the wooden floor bar, it is necessary to use specialized tools and construction procedures in accordance with the recommended technical requirements. So how is the construction of outdoor wooden planks to correct technical requirements?

Step 1: Prepare tools and site treatment

Tools necessary to construct AWood outdoor plastic wood include: beam, drill, splint, electric saw, stainless steel screws, dowels, AWood plastic wood, ... In addition, ensure the construction ground with the difference. height of each floor area does not exceed 5 mm for the finished floor to achieve ideal balance.

Step 2: Construction of outdoor wooden floors

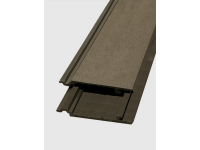

Arrange the fly bars parallel to each other with a distance between the bars is 30-35cm and the distance between the two beams is 2cm from the dark wall. Existing beams have a standard size of 3.3m / bar, usually with 2 opposite grooves, shallow and deep grooves. When constructing the fly bar we direct the shallow groove upwards and the deep groove down to the ground and fix the fly bar by drilling holes in the ground and fixing with screws and off the bar.

Place the outdoor wooden planks in turn in a direction perpendicular to the preloaded beam with a distance between the plank head and the wall base of 5mm. Use pins to fix the wooden planks together and reattach the same operation with other wooden boards until the work is completed. To ensure the quality of the floor, there must be a minimum distance between 2 wood flooring boards is 3mm and should top the wooden plank and the outdoor beam to complete the floor with the most optimal aesthetic beauty.

Step 3: Inspect work completion

Check the wood joints to see if the wood board spacing is even, the edge is secure and if it is detected that the floor board is chipped or warped, remove it, reinstall and fix it with screws. Sanitize the floor surface with specialized detergent and hand it over to the user.

Top 18 outdoor garden wooden floors

.png)

comment(s)