- KHO SÀN GỖ BÌNH TÂN 254 Nguyễn Thị Tú, Bình Hưng Hoà B, Bình Tân, HCM

Tel/Zalo: 084 8888 254 - KHO SÀN GỖ BÌNH CHÁNH 114 Đường số 12 KDC Phong Phú 4, Phong Phú, Bình Chánh, HCM

Tel/Zalo: 090 8888 795 - KHO SÀN GỖ BÌNH THẠNH 443 Bạch Đằng, Phường 2, Quận Bình Thạnh, HCM

Tel/Zalo: 091 8888 443 - KHO SÀN GỖ CỦ CHI 410 Tổ 1, Khu Phố 4, Tỉnh lộ 8, Củ Chi, HCM

Tel/Zalo: 0876 8888 56 - KHO SÀN GỖ GÒ VẤP 957 Phan Văn Trị, Phường 7, Quận Gò Vấp, HCM

Tel/Zalo: 092 8888 181 - KHO SÀN GỖ HCM 209 Tô Hiến Thành, Phường 13, Quận 10, HCM

Tel/Zalo: 0913 8888 01 - KHO SÀN GỖ HÓC MÔN 249 Tô Ký, Tân Xuân, Hóc Môn, HCM

Tel/Zalo: 094 8888 249 - KHO SÀN GỖ KHA VẠN CÂN 867 Kha Vạn Cân, Linh Tây, Thủ Đức, HCM

Tel/Zalo: 081 8888 528 - KHO SÀN GỖ NHÀ BÈ số 9 Nguyễn Hữu Thọ, Phước Kiển, Nhà Bè, HCM

Tel/Zalo: 089 8888 081 - KHO SÀN GỖ PHÚ NHUẬN 247A/9 Huỳnh Văn Bánh, Phú Nhuận, HCM

Tel/Zalo: 091 8888 174 - KHO SÀN GỖ PHƯỚC LONG A 81 Tây Hoà, Phước long A, Quận 9, Thủ Đức, HCM

Tel/Zalo: 085 888 8067 - KHO SÀN GỖ QUẬN 2 91 Lương Định Của, Phường Bình An, Quận 2, HCM

Tel/Zalo: 0946 8888 91 - KHO SÀN GỖ QUẬN 6 68A Đặng Nguyên Cẩn, Phường 14, Q6, HCM

Tel/Zalo: 097 8888 395 - KHO SÀN GỖ QUẬN 7 444A Nguyễn Văn Linh, Tân Phú, Quận 7, HCM

Tel/Zalo: 091 8888 923 - KHO SÀN GỖ QUẬN 8 146 Phạm Hùng, X. Bình Hưng, Bình Chánh, HCM

Tel/Zalo: 091 8888 315 - KHO SÀN GỖ QUẬN 9 15 Dương Đình Hội, Phước Long B, Quận 9, HCM

Tel/Zalo: 091 8888 951 - KHO SÀN GỖ QUẬN 10 281 Lý Thái Tổ, Phường 9, Quận 10, HCM

Tel/Zalo: 092 8888 281 - KHO SÀN GỖ QUẬN 11 343Q Lạc Long Quân, Phường 5, Quận 11, HCM

Tel/Zalo: 091 8888 617 - KHO SÀN GỖ QUẬN 12 484 Nguyễn Văn Quá, Đông Hưng Thuận, Quận 12, HCM

Tel/Zalo: 0913 8888 20 - KHO SÀN GỖ QUẬN TÂN BÌNH 760 Lạc Long Quân, Phường 9, Quận Tân Bình, HCM

Tel/Zalo: 091 88888 75 - KHO SÀN GỖ SÀI GÒN 223 Phan Huy Ích, Phường 14, Gò Vấp, HCM

Tel/Zalo: 091 8888 223 - KHO SÀN GỖ TÂN BÌNH 113 Tân Hải, Phường 13, Quận Tân Bình, HCM

Tel: 094 8888 057 - KHO SÀN GỖ TÂN PHÚ 249 Trần Thủ Độ, Phú Thạnh, Tân Phú, HCM

Tel/Zalo: 090 8888 916 - KHO SÀN GỖ TÂN TẠO 156/13/2 Lê Đình Cẩn, Tân Tạo, Bình Tân, HCM

Tel/Zalo: 091 8888 721 - KHO SÀN GỖ THỦ ĐỨC 610 Quốc Lộ 13, Hiệp Bình Phước, Thủ Đức, HCM

Tel/Zalo: 081 8888 610 - KHO SÀN GỖ THỦ ĐỨC(Tam Phú) 234 M Tam Bình, Tam Phú, Thủ Đức, HCM

Tel/Zalo: 0924 8888 34 - KHO SÀN GỖ CẦN GIỜ 2795 Huỳnh Tấn Phát, Ấp 6, Phú Xuân, Nhà Bè, HCM

Tel/Zalo: 089 8888 723

- KHO SÀN GỖ HÀ NỘI 338 Giải Phóng, Phương Liệt, Thanh Xuân, Hà Nội

Tel: 091 8888 601 - KHO SÀN GỖ HÀ ĐÔNG Số 01, BT5 Khu đô thị Phú Lương, Hà Đông, Hà Nội

Tel: 091 8888 619 - KHO SÀN GỖ TÂY HỒ 594B Lạc Long Quân, P. Nhật Tân, Q. Tây Hồ. Hà Nội

Tel: 091 8888 927 - KHO SÀN GỖ SÓC SƠN 68 Đường 16, Thôn Phú Thọ, Đông Xuân, Sóc Sơn, Hà Nội

Tel: 091 8888 561 - KHO SÀN GỖ MỸ ĐÌNH 123 Nguyễn Văn Giáp, Nam Từ Liêm, Hà Nội

Tel: 091 8888 122 - KHO SÀN GỖ LONG BIÊN 583 Ngô Gia Tự, Đức Giang, Long Biên, Hà Nội

Tel: 091 8888 270

- KHO SÀN GỖ CẨM LỆ ĐÀ NẴNG 34 Ông Ích Đường, Thọ Hòa Tây, Cẩm Lệ, Đà Nẵng

Tel: 091 8888 715 - KHO SÀN GỖ HÒA XUÂN ĐÀ NẴNG 65 Võ Chí Công, Hòa Xuân, Cẩm lệ, Đà Nẵng

Tel: 093 8888 957

- KHO SÀN GỖ BIÊN HÒA 126B, Quốc Lộ 1A, khu phố 4, Tân Hiệp, Biên Hòa, Đồng Nai

Tel/Zalo: 089 8888 005 - 091 8888 647 - KHO SÀN GỖ TRẢNG BOM Số 5/4 Lộc Hoà, QL1A, Tây Hoà, Trảng Bom, Ðồng Nai

Tel/Zalo: 091 8888 061 - KHO SÀN GỖ LONG THÀNH Tổ 10 Phạm Văn Đồng, khu Cầu Xéo, Long Thành, Đồng Nai

Tel/Zalo: 091 8888 146 - KHO SÀN GỖ GIA KIỆM 35/2E Quốc lộ 20, Thống Nhất, Ðồng Nai

Tel: 090 8888 635 - KHO SÀN GỖ XUÂN LỘC 404 Hùng Vương, Gia Ray, Xuân Lộc, Đồng Nai

Tel: 081 8888 433 - KHO SÀN GỖ ĐỊNH QUÁN 54 Phố 2, Ấp 3, Phú Lợi, Định Quán, Đồng Nai

Tel: 081 8888 764 - KHO SÀN GỖ LONG KHÁNH Số 1 Quốc Lộ 1A , Đường 21 tháng 4 , KP Núi Tung , TP. Long Khánh , Đồng Nai

Tel: 085 8888 781

- KHO SÀN GỖ BÀ RỊA 75 Nguyễn Tất Thành, Phước Nguyễn, Bà Rịa, Bà Rịa - Vũng Tàu, Vietnam

Tel/Zalo: 0813 9999 72

- SHOWROOm SÀN GỖ VŨNG TÀU 170A Huyền Trân Công Chúa, Phường 8, Vũng Tàu

Tel: 091 8888 165 - KHO SÀN GỖ VŨNG TÀU 117 Huyền Trân Công Chúa, Phường 8, Vũng Tàu

Tel: 081 8888 165

- KHO SÀN GỖ BÌNH DƯƠNG 62 Phạm Ngọc Thạch, Hiệp Thành, Thủ Dầu Một, Bình Dương

Tel/Zalo: 089 8888 062 - 090 8888 062

- KHO SÀN GỖ BÌNH PHƯỚC 729 Quốc lộ 14, Tân Bình, Đồng Xoài, Binh Phước

Tel/Zalo: 089 8888 729 - 090 8888 193

- KHO SÀN GỖ TÂY NINH 445 Lạc Long Quân, Hiệp Tân, Hoà Thành, Tây Ninh

Tel: 089 8888 250 - KHO SÀN GỖ TRẢNG BÀNG 244A Nguyễn Văn Rốp, Trảng Bàng, Tây Ninh

Tel: 070 8888 170

- KHO SÀN GỖ NHA TRANG Số 7F đường 19/5, CT2 Vĩnh Điềm Trung, Nha Trang, Khánh Hòa

Tel: 091 8888 730 - KHO SÀN GỖ KHÁNH HÒA 442 Lê Hồng Phong, Phước Hải, Nha Trang, Khánh Hoà

Tel: 090 8888 906 - KHO SÀN GỖ PHƯỚC HẢI B1 Chung Cư Lê Hồng Phong, Phước Hải, Nha Trang, Khánh Hoà

Tel: 091 8888 997

- KHO SÀN GỖ LA GI Số 4 Nguyễn Trường Tộ, Phường 10, Lagi, Bình Thuận

Tel: 090 8888 085 - KHO SÀN GỖ PHAN THIẾT 64 Đại Lộ Hùng Vương, Phú Thủy, Phan Thiết

Tel: 091 8888 742

- KHO SÀN GỖ PHAN RANG 95 QL1, Ngã 3 Long bình, Ninh Phước, Phan Rang, Ninh Thuận

Tel: 082 8888 095

- KHO SÀN GỖ BẢO LỘC 15B Nguyễn Văn Cừ, Lộc Sơn, Bảo Lộc, Lâm Đồng

Tel: 090 8888 053 - KHO SÀN GỖ ĐÀ LẠT Số 3 Tô Hiệu, Phường 8, Đà Lạt, Lâm Đồng

Tel/Zalo: 091 8888 506 - KHO SÀN GỖ ĐỨC TRỌNG 358 Quốc Lộ 20, Liên Nghĩa, Đức Trọng, Lâm Đồng

Tel/Zalo: 090 888 80 53

- KHO SÀN GỖ GIA LAI 373 Phạm Văn Đồng, Pleiku, Gia Lai

Tel/Zalo: 089 8888 373 - 091 8888 350

- KHO SÀN GỖ KON TUM 61 Phạm Văn Đồng, Lê Lợi, Kon Tum

Tel/Zalo: 091 8888 137

- KHO SÀN GỖ ĐẮK LẮK 105 Hà Huy Tập, Tân Lợi, Buôn Ma Thuột, Đắk Lắk.

Tel: 091 8888 945 - KHO SÀN GỖ BUÔN MA THUỘT 38 Nguyễn Hữu Thọ, Tân An, Buôn Ma Thuột, Đắk Lắk.

Tel: 0855 8888 02

- KHO SÀN GỖ ĐẮK NÔNG 30 Lê Lai, Nghĩa Trung, Gia Nghĩa, Đắk Nông

Tel: 090 8888 537

- KHO SÀN GỖ QUY NHƠN 114 Đào Tấn, Nhơn Bình, Qui Nhơn, Bình Định

Tel: 090 8888 776 - KHO SÀN GỖ HOÀI NHƠN 92 QL1A, Tam Quan, Hoài Nhơn, Bình Định

Tel: 0965 8888 43 - KHO SÀN GỖ BÌNH ĐỊNH 1213 Trần Hưng Đạo, Đống Đa, Quy Nhơn, Bình Định

Tel: 082 8888 920

- KHO SÀN GỖ PHÚ YÊN 220 Nguyễn Văn Linh, Phú Lâm, Tuy Hòa, Phú Yên

Tel: 090 8888 057 - KHO SÀN GỖ TUY HÒA 138 Lê Lợi, Phường 4, Tuy Hòa, Phú Yên

Tel: 082 8888 078

- KHO SÀN GỖ QUẢNG NGÃI 180 Hai Bà Trưng, Lê Hồng Phong, Quảng Ngãi

Tel: 091 8888 274

- KHO SÀN GỖ QUẢNG NAM 130 Nguyễn Văn Trỗi, Tân Thạnh, Tam Kỳ, Quảng Nam

Tel: 094 8888 130

- KHO SÀN GỖ HUẾ 34 Hoàng Quốc Việt, An Đông, Huế, Thừa Thiên Huế

Tel: 0764 8888 27

- KHO SÀN GỖ QUẢNG TRỊ 399 Quốc Lộ 9, Đông Hà, Quảng Trị

Tel: 0969 8888 74

- KHO SÀN GỖ QUẢNG BÌNH 545A Lý Thường Kiệt, Đồng Phú, Đồng Hới, Quảng Bình.

Tel: 094 8888 973

- KHO SÀN GỖ NGHỆ AN 52, Phạm Đình Toái, Hà Huy Tập, Vinh, Nghệ An

Tel: 091 8888 480 - KHO SÀN GỖ CỬA LÒ 350 Phạm Nguyễn Du, Nghi Hải, Cửa Lò, Vinh, Nghệ An

Tel: 0902 8888 37 - KHO SÀN GỖ QUÁN HÀNH Đ. Xã Đoài, Khối 6, Nghi Lộc, Nghệ An

Tel: 094 8888 231

- KHO SÀN GỖ QUẢNG NINH Lô 8, Hà Khánh C, Hạ Long, Quảng Ninh

Tel: 091 8888 820

- KHO SÀN GỖ LONG AN 90 Hùng Vương, Tân An, Long An

Tel: 091 8888 097

- KHO SÀN GỖ TIỀN GIANG 282 Lý Thường Kiệt, Phường 5, Mỹ Tho, Tiền Giang

Tel: 052 88888 98 - KHO SÀN GỖ MỸ THO 286-288 Nguyễn Công Bình, Mỹ Tho, Tiền Giang

Tel: 079 8888 282

- KHO SÀN GỖ BẾN TRE 181A3 Khu Phố 3, Phú Tân, Bến Tre

Tel: 083 8888 065

- KHO SÀN GỖ VĨNH LONG 94 Ba Tháng Hai, Phường 1, Vĩnh Long

Tel: 092 8888 955

- KHO SÀN GỖ ĐÔNG THÁP 68 Vành Đai, tổ 18, Hoà Khánh, Hòa An, Cao Lãnh, Đồng Tháp

Tel: 0898 888 937

- KHO SÀN GỖ CẦN THƠ 218 Đường 3-2, Hưng Lợi, Ninh kiều, Cần Thơ

Tel: 091 8888 677

- KHO SÀN GỖ BẠC LIÊU 42A Tôn Đức Thắng, Khóm 7, Phường 1, Bạc Liêu.

Tel: 091 8888 294

- KHO SÀN GỖ CÀ MAU 164 Ba Tháng Hai, Phường 5, Cà Mau.

Tel: 082 8888 276

- KHO SÀN GỖ CHÂU ĐỐC 140 Trưng Nữ Vương, Châu Phú B, Châu Đốc, An Giang.

Tel: 098 888 4640

- KHO SÀN GỖ KIÊN GIANG 187 Quang Trung, P. Vĩnh Quang, Rạch Giá, Kiên Giang.

Tel: 0817 8888 23 - KHO SÀN GỖ PHÚ QUÝ Lô P1-13 Đường 3/2, P. An Hoà, Rạch Giá, Kiên Giang.

Tel: 091 8888 316

- KHO SÀN GỖ PHÚ QUỐC 38 Mạc Cửu, Khu Phố 4, Dương Đông, Phú Quốc, Kiên Giang

Tel: 091 8888 402

TƯ VẤN MIỄN PHÍ: 1800 6121 - Hotline: 0913.8888.01 - 0913.8888.02 (Viber / Zalo) - LIÊN HỆ

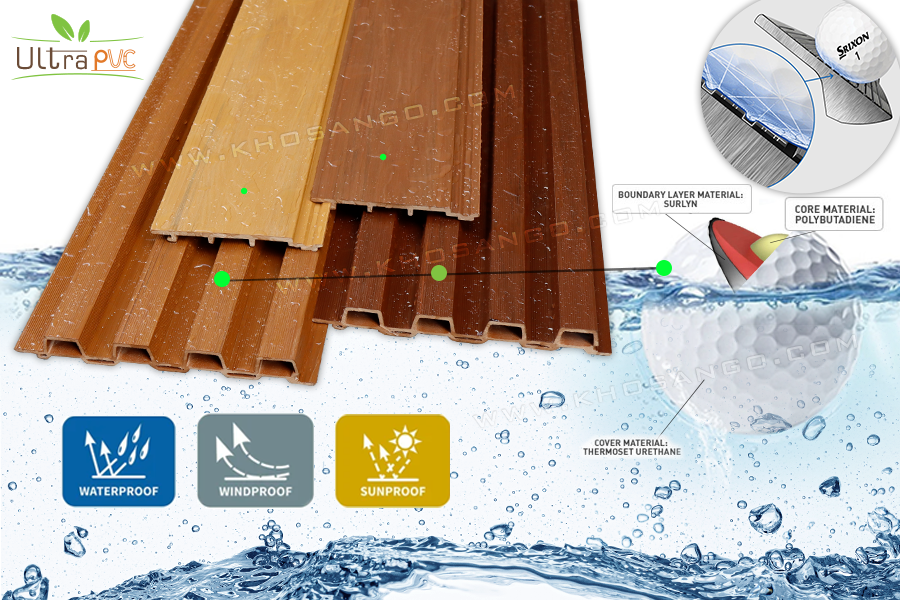

Ultra PVC Wood Composite

ULTRA PVC : WOOD + PVC PLASTIC + ULTRASHIELD SUPER PROTECTION CLASS:

Outdoor decoration with wood plastic WPC has become popular for its natural beauty and is an eco-friendly material. To meet the increasing demand for aesthetics and sustainability, the manufacturer has used Ultrashield technology, a super protective layer that has many advantages such as: ability to withstand all weather extremes, long life, anti-termites , crack-proof, non-toxic, eco-friendly, flame-retardant, fire-resistant, water-resistant and easy to install and maintain.

Accompanying with WPC (wood plastic composite) technology using:

Formula 1: wood + PP/PE plastic with a similar formula also called wood plastic composite or wood plastic composite (WPC) is:

Formula 2: wood + PVC resin, with these two formulas, the mixing ratio of plastic + wood is similar, the only difference is the use of PP/PE or PVC plastic

The same basic formula and similar production line form the same product in terms of size and color. However, the quality is very different: the stability of the form and the color is unknown after outdoor use. The quality of wood plastic composite (WPC) is determined by the granulation technology and adhesive additives. experience (heat know-how)

The general formula of WPC is to use wood + PP / PE / PVC plastic, all using homemade plastic beads (green materials) to clean up waste plastic yards to clean the environment, adding a favorite part to WPC is less the use of forest trees, keeping the environment green and still green (1st generation WPC)

WPC ingredients are wood + resin + additives also have colorants, to color WPC manufacturers have added inorganic or organic dyes to create the relative color uniformity of the product up to 95%. For WPC products with light (white) color, the manufacturer must remove the grain (whiten) before production. This is almost the same way you dye your hair white. WPC with light color will cost about 15% more to produce

With modern grain separation and color separation technology, WPC is produced with the right wood color + plastic color = WPC color, this way does not cost money for dyes and the finished color WPC is stable for a long time outdoors from 5 - 10 years (2nd generation WPC letter)

The advantage of grain separation technology to produce WPC is that it has a stable natural color, the disadvantage is that the color uniformity of this type of WPC surface is only the highest 90%, for those who love carpentry, because of this difference, it also creates For the landscape to be more suitable for nature, for young people who have color digitization formulas, this difference is convenient and the 3rd generation WPC was born with the Ultrashield coat.

Ultrashield layer of plastic technology covers the surface of the material to protect the aesthetics and color of the surface. Ultrashield's composition is a compound: primary HDPE plastic + urethane = Polyurethane(PU) + plastic Surlyn Covers plastic technology, for a realistic description, please see the surface coating on the Gofl fruit.

Ultrashield surface is the current advanced coating technology, adding the advantage that many projects are interested in is the non-stick material, resistant to 100% wet environment.

AWood WPC developed the 3rd generation with a super protective all-round coat called Ultrashield : Ultra Wood Decking and Ultra Wood WPC

Along with Awood WPC using PP/PE plastic is the same WPC formula using PVC according to the development process of technology from the 1st, 2nd and 3rd generation:

1/ Outdoor PVC: use 100% PVC to withstand the outdoors and have to use paint and periodic maintenance

2/ WPC formula: using PVC + wood pulp = wood plastic composite for outdoor use

3/ Ultrashield PVC outer layer = ULTRA PVC : forming a finished product with the basic advantages of PVC:

+ Flame-retardant PVC plastic (burned, not ignited to other objects)

+ PVC plastic has a specific weight of 30 - 50% lighter than PP/PE

+ PVC plastic is safe for users and environmentally friendly.

Ultra PVC: this same use of the 3rd generation outdoor plastic wood meets the needs of outdoor decoration with the lowest cost and the most durable use time.

*Warranty: 15 years outdoor use, eternal material for interior decoration. With a super protective jacket that allows Ultra PVC to be durable with the longest time of use and the lowest maintenance costs.

Ingredients of Ultra PVC: 30% PVC (recycled) 60% wood fiber 5% additives and 5% Polyurethan(PU) for outer coating is super protective coating: UV film against fading, anti-oxidation, anti-mold, adhesives, strengthen bearing (250kg / dm2), dust-proof and 100% waterproof.

The new product is manufactured by developed technology - Ultrashield Layer which is super protective film from the United States since 2010

Double extrusion technique: extruding two of WPC core materials and Polyurethan(PU) coating surrounding 360 overview at the same time to create a solid form.

Ultrashield Layer is an ultra-protective film: to create a layer looks like wood and colorful and the inner layer can meet the requirements for other mechanic and physical properties being suitable for outdoor with temperature from - 400C ~ +700C

Ultra PVC is a wood-plastic mixture covered by advanced Ultrashield layer that surrounds all four sides around its inner core. The Ultrashield class uses an advanced engineering polymer to create a formula that delivers optimal Ultra PVC products against environmental effects as follows:

| 1/ Waterproof, anti-rotting: Ultrashield layer is effective waterproof because its water absorption capacity is less than 1% | 7/ Anti-fading: Ultrashield Layer against UV which protects product colors is long lasting |

| 2/ Against termites, mold and insects: Ultrashield layer effectively protects the attack of insects and mold | 8/ Easy installation: can screw, sand, cut and drill easily by popular construction tools. |

| 3/ Warranty 15 years : the life cycle of Ultra PVC products is over 25 years compared to natural wood of 8 years | 9/ Insulation and sound insulation: prevent 95 - 97% of the heat radiation from outside. Moreovers, Ultrashield can reduce noise by 60-70% |

| 4/ Abrasion resistance: Ultra PVC products are strengthened hard surface, scratch and abrasion better than conventional wood polymer composite. | 10/ Natural wood-like surface: The Ultrashield layer gets a variety of colors with many wood vein: 3D surface, embossed, scratched, wavy, grain wood |

| 5/ Environmentally friendly: Ultra PVC products are manufactured from recycled materials, without causing environmental pollution. | 11/ Thermal insulation: Ultra PVC is able to adapt to variable temperatures ranging from -40 degrees C to 70 degrees Celsius |

| 6/ Ultra PVC No painting: Finish material, no maintenance | 12/ Ultra PVC Easy to clean: Ultrawood surface does not get dirt so it easy to clean with water without detergent |

The product adds value to the places where it is used and adds aesthetics and beauty to the building.

Ultra PVC is latest product line with unique colors, designs and features is the surface treatment by Ultrashield layer for the most natural feeling when hand-touch or walking barefoot. Safe for children, adults and pets.

Multi-application of Ultra PVC: decorative application for many designs that replace wooden and wood plastic composite from indoors to outdoors: wall cladding, ceiling, lamri, shading, fences and gates, stairs, balcony,.... This material is permanent for interior and warrantied 15years for exterior: with the environment that is usually changes even the marine environment cannot effect Ultra PVC.

After decorating with Ultra PVC, All you need to do is sit back and enjoy the beauty of the new floor with your family and never want to leave.

3K HOME WAREHOUSE chains distributes Ultra PVC that companions with you and your home through the country and provides completely installation services with the best service utilities.

FREE SERVICE:

- Survey, measurement, estimation - quotation.

- Consult samples at home 24/7 (from 07h - 21h, Monday to Sunday)

------ ♦️ ♦️ ♦️ ♦️ ♦️ ------

☎️ Call Center : 1800 6121 / Holine: 0913 8888 01 (Zalo/viber)

* Suggestion box: 0918888820 (Zalo/viber)

Facebook Comments

.png)