What is Wood Plastic Composite? Quotation of genuine wood plastic composite

Existing interior and exterior finishing materials always direct the user's life closer to nature, protect the environment with long material life, save costs, and improve the quality of life. An ideal living space ensures the harmony between the design inside and outside the house to achieve architectural balance, giving people comfort wherever they live.

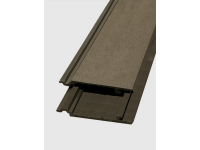

Exterior space is a place that is directly exposed to sunlight and erratic changes of weather, making it difficult to choose decorative materials with long life, less material loss over time. Wood plastic composite with texture from primary plastic, stone powder, wood powder and additives for direct outdoor use with long life, stability over time is the best choice at present.

What is Wood Plastic Composite?

Wood Plastic Composite (Wood Plastic Composite) or outdoor plastic wood is a composite flooring material made from wood pulp and plastic with the ideal ratio: 55% natural wood pulp, PE-PVC virgin plastic resin 36 %, stone powder 6% and adhesive 3% extruded and shaped depending on the flooring brand.

Wood plastic composite with raw wood pulp materials: sawdust, pulp, legume shells, bark, raw wood, ... mixed with synthetic resins: HDPE, PVC, PP, ABS, PS, PE,... additives such as colorants, stabilizers, hardeners, emulsifiers, adhesives, anti-disintegration agents, etc., give birth to a product line that combines all the outstanding advantages for direct use. exposure to sunlight and long-term weather changes.

Quotation of genuine wood plastic composite

Exterior space is a place that is directly exposed to sunlight and erratic changes of weather, making it difficult to choose decorative materials with long life, less material loss over time. Wood plastic composite with texture from primary plastic, stone powder, wood powder and additives for direct outdoor use with long life, stability over time is the best choice at present.

What is Wood Plastic Composite?

Wood Plastic Composite (Wood Plastic Composite) or outdoor plastic wood is a composite flooring material made from wood pulp and plastic with the ideal ratio: 55% natural wood pulp, PE-PVC virgin plastic resin 36 %, stone powder 6% and adhesive 3% extruded and shaped depending on the flooring brand.

Wood plastic composite with raw wood pulp materials: sawdust, pulp, legume shells, bark, raw wood, ... mixed with synthetic resins: HDPE, PVC, PP, ABS, PS, PE,... additives such as colorants, stabilizers, hardeners, emulsifiers, adhesives, anti-disintegration agents, etc., give birth to a product line that combines all the outstanding advantages for direct use. exposure to sunlight and long-term weather changes.

Quotation of genuine wood plastic composite

No. Product name Specification (L x W x H) Price

Quote genuine wood plastic composite accessories

No. Product name Specification (L x W x H) Price

first

Quotation for finishing construction of wood plastic composite and shipping costs

Features of Wood Plastic Composite

With synthetic materials, Wood Plastic Composite can be more diverse in finishing shapes depending on the manufacturer and the user's needs. Wood plastic composite is close to the current best additives to produce products for direct use, without the need for surface protection paint like traditional materials, but still ensures environmental friendliness, color durability over time. time. Wood plastic composite is a material that should be invested for long-term use, no maintenance costs with low finishing costs, aesthetics and quality are confirmed. So what are the outstanding advantages and disadvantages of WPC plastic wood?

Advantage:

Wood plastic composite is the leading material for exterior space not only because of the finishing cost and stability but also the outstanding advantages of this material that won the hearts of many people.

Water resistance: the top criterion that determines the quality of wood is water resistance, especially outdoor wood materials where it is directly exposed to water and temperature. Wood plastic composite is extremely water resistant, suitable even for high humidity areas such as swimming pools and coastal resorts.

Anti-termite, moldy: because of frequent exposure to sunlight and rain, mold and termites are always a concern for many people because this harmful agent directly affects the life of the material. Wood plastic composite is not moldy and extremely sturdy, not chipped by termites.

Material shrinkage and expansion: Wood plastic composite does NOT shrink or expand material under weather changes. The product is durable, the aesthetics are stable over time.

Fireproof, heat resistant: Wood plastic composite does not catch fire, so it does not burn and has good insulation. If the outside temperature exceeds the flammability threshold during prolonged direct surface contact, the product will discolor the surface.

Bearing: The bearing capacity of wood plastic composite is extremely good, users can use this flooring material as wooden columns and pergola simply because the load capacity is similar to natural wood.

Easy to shape: the material's light weight and ease of shaping allows users to create a space for exterior decoration with simple and luxurious composite wood-plastic materials.

Price: Wood plastic composite is absolutely safe for users' health and effectively protects the environment. Finished plastic composite wood is cheaper than natural wood, saving costs for users.

Weakness:

Although the load capacity of wood plastic composite is good, but due to its lighter weight, the hardness is still not higher than that of natural wood.

If the temperature exceeds the material threshold, plastic wood can be deformed because the composition with 36% is primary plastic resin.

Wood Plastic Composite Application

The current Pergola flower truss construction not only gives customers the space to relax, party, .. but also show the simplest class of homeowners. Pergola flower truss can bring back a luxurious highlight that attracts all eyes when constructed with Composite wood and plastic materials, and if you combine the flower truss with the pool space, the space will be more harmoniously combined.

A smartly decorated outdoor space, harmoniously combining relaxation and relaxation elements will be the best place to balance life that everyone is aiming for. High-grade Awood plastic wood is also an indispensable material to enhance the current living space that no other exterior material can compare both in terms of finished beauty, quality, and longevity in long-term use.

Genuine wood plastic composite distribution address

The current distribution address of genuine Wood Plastic Composite which is trusted by many people is the nationwide wooden floor warehouse system. Dedicated consulting, clear trading, quick construction and full-fledged warranty are the customer care policies that Wood Floor Warehouse aims to bring the best experience to users, improve the quality of life. Vietnamese family life.

To grasp the details of the latest Wood Plastic Composite information and the annual promotions of the Wood Floor Warehouse system, you can contact us directly at the free consultation call center.

Hotline: 1800 6121

Website: khosango.com

Contact list of Wood Floor Warehouse branches nationwide.

The leading wood flooring distribution system in Vietnam - Wood floor warehouse

.png)

comment(s)